Wednesday, September 20, 2017

Results and Reflections

After seeing each group's product, we averaged out the results on our rubric:

Team International's Key Clip - 8/8

Kangas' Speaker - 7/8

Pachas' Chin Guard - 5/8

Pioneer's Charger Clip - 6/8

We liked Team International's product the best due to the functionality, durability, and cleanness.

Criteria Does not meet

(0 points)

Meets (1 point)

Exceeds (2 points)

Functionality: Product cannot preform or breaks under stress

Has some set backs but able to work just not at full capacity

Product is able to faction normally and as designed

Durability: Gadget cannot break away from support

Gadget can break away but cannot preform function needed to full capacity

Gadget is able to break away from support pieces and is sturdy enough to preform the function needed

Is it 3D printable Product: either collapses while printing or is not able to come out cleanly

Able to print with some setbacks/limits

Able to print with no problems whatsoever

Easy to clean

too much support to have a clean product

Able to break away from support but not completely clean from access material

Final product is clean or easy to break off of supports

(0 points)

Meets (1 point)

Exceeds (2 points)

Functionality: Product cannot preform or breaks under stress

Has some set backs but able to work just not at full capacity

Product is able to faction normally and as designed

Durability: Gadget cannot break away from support

Gadget can break away but cannot preform function needed to full capacity

Gadget is able to break away from support pieces and is sturdy enough to preform the function needed

Is it 3D printable Product: either collapses while printing or is not able to come out cleanly

Able to print with some setbacks/limits

Able to print with no problems whatsoever

Easy to clean

too much support to have a clean product

Able to break away from support but not completely clean from access material

Final product is clean or easy to break off of supports

As for the hand held bottle opener. the opening piece the goes on the cap seems to be a little small, Also the lever piece seems to very weak so it might break off. Also there should be 4 finger places instead of 3. I think the overall shape be ok just some sizing differences should make it better

For Nick's handheld bottle opener, it looks to be a little blocky of a design. It could use more rounded edges to make it look smoother. It also looks a bit thin, so I'm not sure if it could successfully open a bottle. I think with a couple of tinkers, it could be very successful.

For our limitation design, we made a zipper to test how small and detailed the 3D printer can get. The zipper pieces fell apart once we took them off of the support pieces. This means that when printing you need to have you design big enough to be able to be pulled apart form the support.

For the helicopter design, the amount of support needed to be broken down was excessive. It took forever to breakdown and in that process, it broke certain pieces off. Other than that I realize that when building a design like that before printing, it might be easier to build in separate designs and just put it together when everything is taken a second

For Nick's handheld bottle opener, it looks to be a little blocky of a design. It could use more rounded edges to make it look smoother. It also looks a bit thin, so I'm not sure if it could successfully open a bottle. I think with a couple of tinkers, it could be very successful.

For our limitation design, we made a zipper to test how small and detailed the 3D printer can get. The zipper pieces fell apart once we took them off of the support pieces. This means that when printing you need to have you design big enough to be able to be pulled apart form the support.

For the helicopter design, the amount of support needed to be broken down was excessive. It took forever to breakdown and in that process, it broke certain pieces off. Other than that I realize that when building a design like that before printing, it might be easier to build in separate designs and just put it together when everything is taken a second

Wednesday, September 13, 2017

Clip: the clip idea had the lever of the piece that comes out going the other way so no chains would come out. they had a very well done design on TinkerCAD and it looked like it will work well. the pin idea is very smart because there is one piece that will fit in the whole and one bigger piece that will make sure it stays in place .

Speaker: Although the design looks simple when the layers were ungrouped it showed that they layered to make the walls of the speakers stronger. From the looks of it, it will work very well.

Shin Guard: The shin guard model looked very good. It looked like it could perfectly fit around a chin and guard it efficiently. They would need to add some kind of padding to make it useful in a read game, and they said they would. So they have it planned out pretty well for practical use. Overall, I really liked the sleek look of the design and smooth edges. The guard was thick enough so that it wouldn't shatter easily and it looked lightweight. It was a good design.

Wire Guard: The wire guard is coming along nicely. The group members expressed some difficulty in the design because there is an issue not only giving the wire enough support to be functional, which requires the gap to be tighter. On the other side of the coin, the gap can't be too tight if not the wire can't actually be inserted.

Speaker: Although the design looks simple when the layers were ungrouped it showed that they layered to make the walls of the speakers stronger. From the looks of it, it will work very well.

Shin Guard: The shin guard model looked very good. It looked like it could perfectly fit around a chin and guard it efficiently. They would need to add some kind of padding to make it useful in a read game, and they said they would. So they have it planned out pretty well for practical use. Overall, I really liked the sleek look of the design and smooth edges. The guard was thick enough so that it wouldn't shatter easily and it looked lightweight. It was a good design.

Wire Guard: The wire guard is coming along nicely. The group members expressed some difficulty in the design because there is an issue not only giving the wire enough support to be functional, which requires the gap to be tighter. On the other side of the coin, the gap can't be too tight if not the wire can't actually be inserted.

Limitations of the 3D printer

For the first design, we are testing out the drying time of the plastic. we are thinking that if you have only a small connection with two pieces off of the base that the plastic will not dry enough and start to droop down. the second design we tested the size capability of the printer. We are hearing about 3D printing body parts which can be pretty big. If you wanted to build a chair or something, you would be limited to only having to print out the pieces and not the whole chair as a whole. The last design will test the accuracy of the printer. If you needed a part to have exact dimensions on a small scale the printer. For zippers, the whole design relays on being lined up exactly on a small scale.

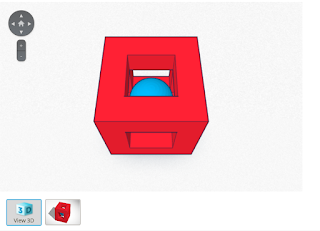

TinkerCAD Cube

The physical cub that we got from the cube was 1 inch by 1 inch by 1 inch. the small square holes on each face of the cube is 1/2 inch by 1/2 inch making the remaining amount around the holes 1/4 inch. As for the ball, we guessed that the ball has a 1/2 inch diameter because it looked like it lined up perfectly with the hollowed out square on each side.

On TinkerCAD, the dimensions all the dimensions seemed to be halved, so the whole cube is 1/2 inch by 1/2 inch.

This bottle opener design is similar to out with the finer hole on the back end and the hook on the opposite side. The only real difference is the hooking action our is more of a pull while this design is a hooking or pushing. When deconstructing and ungrouping this design had a lot more holes and cuts while in comparison, our design is set up with more shapes and fewer holes.

Friday, September 8, 2017

What Happened in the Tutorials

In the tutorials we learned the basics of the program of how to move the camera and shape on a X,Y,Z axis. The possibilities are endless if your imagination and creativity are.

Wednesday, September 6, 2017

Tinkercad Tutorial

During this TinkerCad tutorial, I learned all the basics of TinkerCad. I learned how to cut shapes, make objects, resize them and much more. I am looking forward to making my newly engineered objects and using this app to 3D Print them. This relates to engineering because this is a creator's app that can be used to craft objects and then print them to test them out in real life.

Redesign

1 We made very minimal changes to our designs. as for the full handled opener, we adjusted the angle at which the two parts come together. this causes a more comfortable grip and movement as you open the bottle.

2 The main design was altered minimally. The tail of the piece was given a little more length so the user could have a little more leverage. Another change that was added was how the bottle cap will sit onto the system with a little edge added by the hook. Lastly a little hole was added onto the tail so a key chain could be added.

3 The design was changed into a more efficient, slick looking model. Instead of the hook like opener, I changed it into a double sided compartment where the cap fits in between the two openers and you crank the opener and it will smoothly open. This design makes it so there is a cleaner, smoother open, with little to no chance of spilling any liquid because it will come off quickly and effortlessly.

4 the design was not altered that much. When working in the design program I changed how the bottle will hook to the actual cap. It gives the bottle a more slick design and makes it look better.

2 The main design was altered minimally. The tail of the piece was given a little more length so the user could have a little more leverage. Another change that was added was how the bottle cap will sit onto the system with a little edge added by the hook. Lastly a little hole was added onto the tail so a key chain could be added.

3 The design was changed into a more efficient, slick looking model. Instead of the hook like opener, I changed it into a double sided compartment where the cap fits in between the two openers and you crank the opener and it will smoothly open. This design makes it so there is a cleaner, smoother open, with little to no chance of spilling any liquid because it will come off quickly and effortlessly.

4 the design was not altered that much. When working in the design program I changed how the bottle will hook to the actual cap. It gives the bottle a more slick design and makes it look better.

2 other ideas

The two other ideas that we could have made were a phone case with a built in card holder and water flavoring straw. we did not choose to make these because we thought a bottle opener would be more useful. the practicality of the bottle opener out weighs those of the phone case and straw. Also we thought we could make cooler designs with bottle opener than straws and phone cases.

Subscribe to:

Comments (Atom)

course outline

Course as is week 1-5 3d printing week 6 Engineering as a whole week 7-8 analytics week 9-12 LEGO week 13-14 Christmas lights week 15 ...

-

During this TinkerCad tutorial, I learned all the basics of TinkerCad. I learned how to cut shapes, make objects, resize them and much mo...

-

https://docs.google.com/document/d/1dijjRktnnzJaujDWoLtJrbMGqJjdb80ZfgIrYegjskQ/edit?usp=sharing